产品中心

联系我们

微信:13952150662

手机:13952150662

电话:0516-87791695

Q Q:705209396

联系人:张经理

http://www.weightec.net/

WTC-JSP集散式皮带秤配料系统Belt scale batching system

WTC-JSP集散式皮带秤配料系统:

威泰克公司研制开发的WTC-JSP集散式皮带秤配料系统(配料秤),是计算机技术、控制技术、通讯技术和图形显示技术相结合的产物,其控制功能完善,显示、操作集中,数据处理方便,安装、维护简单,系统便于扩展。完全适用了现代工业生产的高度自动化和工艺过程控制的日益复杂化。系统广泛应用于冶金、焦化、化工、烧结、球团、选矿、建材、轻工、水泥、食品、化肥等行业。

工作原理:

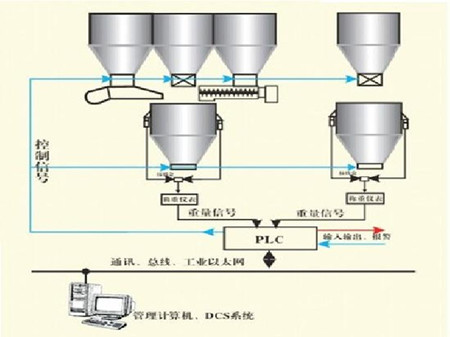

圆盘给料机或其它上位输送机输送物料到单机皮带秤,单机皮带秤的重量信号,速度信号进入积算器,并在积算器内部进行处理和显示,同时,输出与流量成正比的4~20mA电流信号都智能调节器,调节器根据用户设定的PID参数及理想控制值,输出4~20mA电流到电机控制器,并由其调节给料机速度快慢,从而达到控制给料量的目的。上位机通过RS485接口把配比下达到各台调节器,把积算器的累重和流量读入机内进行建库、显示、打印等。

系统组成:

配料系统主要由现场生产设备,单机皮带秤(包括输送机系统、皮带秤体、称重仪表、称重传感器、测速传感器设备)、调节器、变频控制器、PLC、电气控制柜、上位机、系统软件以及料位检测装置等组成。

系统主要特点:

◆称重给料机良好的计量性能为系统提供准确、稳定的基础数据;

◆智能单回路调节器具有PID多种算法,并可实现手动/自动无忧切换;

◆单机启停、顺序启停、料头料尾对齐,上下级设备的连锁、解锁;

◆可根据不同的给料设备选择变频控制器、滑差调速控制器;

◆可设定单台下料量和按比例设定配比量;

◆可选开环或闭环控制功能,以实现系统的智能控制。

主要技术参数:

皮带秤计量误差:≤±0.5%或≤±1.0%

配料系统精度:≤±1.0%或≤±2.0%

环境温度:-20℃~70℃

系统配料能力范围:0~800t/h

可选料位测量精度:±0.5%或±1.0%

电源:380/220VAC、50HZ

电流输出:0~20mA或4~20mA正比于单机皮带秤流量

通讯网络:RS-485/422

wtc-jsp distributed belt scale batching system (batching scale) developed by weikek company is the product of the combination of computer technology, control technology, communication technology and graphic display technology. its control function is perfect, the display and operation are centralized, the data processing is convenient, the installation and maintenance are simple, and the system is easy to expand. fully applicable to the high degree of automation of modern industrial production and the increasing complexity of process control. The system is widely used in metallurgy, coking, chemical, sintering, pellet, mineral processing, building materials, light industry, cement, food, fertilizer and other industries. Working principle: The disk feeder or other upper conveyor conveys material to the single machine belt scale, the weight signal of the single machine belt scale, the speed signal enters the accumulator, and it is processed and displayed inside the accumulator. At the same time, the output of the 4~20mA current signal proportional to the flow rate is all intelligent regulator, and the regulator outputs the 4~20mA current to the motor controller according to the PID parameters set by the user, and adjusts the speed of the feeder to achieve the purpose of controlling the feed quantity. The upper computer sends the ratio to each regulator through the RS485 interface, and reads the accumulator's accumulator's weight and flow rate into the machine to build the library, display, print and so on. System composition: The batching system is mainly composed of field production equipment, single machine belt scale (including conveyor system, belt scale body, weighing instrument, weighing sensor, speed measurement sensor equipment), regulator, frequency conversion controller, PLC, electric control cabinet, upper computer, system software and material level detection device. Key features of the system: The good measuring performance of weighing feeder provides accurate and stable basic data for the system. Intelligent single-loop regulator with PID algorithms, and can achieve manual / automatic worry-free switching; Single machine start and stop, sequence start and stop, material end alignment, upper and lower equipment chain, unlock; ◆ variable frequency controller and slip speed controller can be selected according to different feed equipment; ◆ can set the quantity of single feed and proportion of proportion; ◆ optional open-loop or closed-loop control functions to achieve intelligent control of the system. Main technical parameters: Measuring error of belt scale :≤±0.5% or ≤±1.0% Precision of batching system :≤±1.0% or ≤±2.0% Ambient temperature :-20℃~70℃ System batching capacity range :0~800 t/h Optional level measurement accuracy :±0.5% or ±1.0% Electricity :380/220 VAC、50HZ current output :0~20 mA or 4~20 proportional to the flow rate of a single belt scale Communication network: RS-485/422